Benkovac Test Site

General information

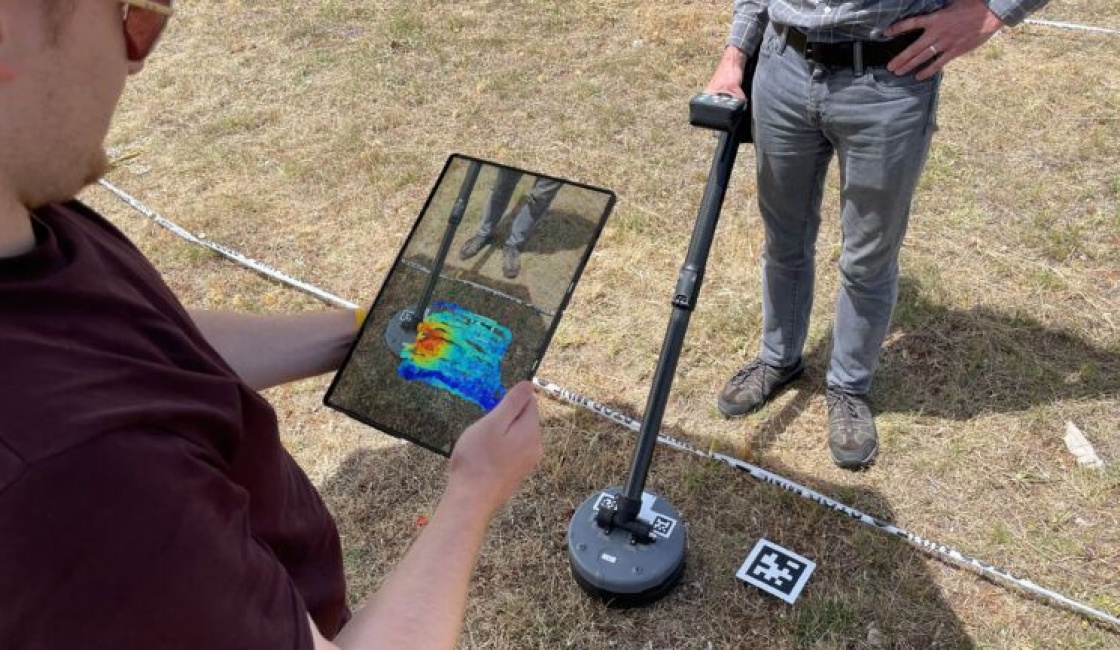

Benkovac test site was established in 2000 for the purpose of testing hand-held mine detection systems and those mounted on vehicles. With development of advanced technologies, the test site is used for testing of robotic systems, biological detection methods, explosives sensors and airborne detection systems.

Test site is located in an open area, with a surface of 10,000 m2.

1000 mine targets buried in 2000.

- Three different soil types

- Office facility: Size: 35 m2

Working hours: Without restriction

Remarks: Advance scheduling obligatory, at least 30 days in advance

Use of explosives: Usage of explosives is allowed, but activation is not allowed. Use of ignition devices and live mine fuses is not allowed.

Entrance requirements: Entry allowed only with HCR-CTRO personnel.

Remarks: Persons planning to enter the test site should register beforehand

Infrastructure available:

Electricity: 220V

Fuel: NO

Water: YES

Compressed air: NO

Canteen: NO

Distance: Hotel: 20 km (Biograd), 30 km (Zadar)

Railway station: 3 km (Benkovac)

Airport: 25 km (Zadar), 110 km (Split)

Sea port 30 km

Test lanes/areas

The test site is divided into 47 lanes

8 lanes are used for training and testing equipment with available data on the type and location of buried mines.

- 30 m long, 1 m wide

- Three types of soil: neighbouring area soil – uncooperative soil, soil from the continental part of Croatia – cooperative-neutral soil and local soil from the test site – uncooperative and heterogeneous

- The following targets were buried:

- antipersonnel mines: PROM-1, PMA-1, PMA 2, PMA 3

- anititank mines: TMRP-6, TMA-3

- UXO - 15 pieces

- part of trombone mines, fragments, PMA-2 surrogates, bullets, aluminium parts, plastic box

Other types of mines may be provided on users request.

39 lines are used for testing and evaluating ground or airborne detection systems. Data are not publicly available.

- 47 m long, 1 m wide

- Mines are buried at 5-27 cm deep. Distance between the lanes is 3 m. The lanes are divided into 1×1 m squares, their furthermost points are marked. The distance of 3 m between the lanes is sufficient to prevent interference from objects in the neighbouring lanes and to enable passage of a vehicle.

- The following types of mines are buried:

- antitank: TMM-1, TMA-1A, TMA-2A, TMA-3, TMA-4, TMA-5, TMRP-6

- antipersonnel: PMA-1A, PMA-2, PMA-3, PMR-2A/2AS, PMR-3, PROM-1

Weather conditions enable the use of the test site all the year round. There is almost no snow or frost, and the rains are rare.

Security

The test site is protected with a fence and there is a 24 hours a day alarm system.

Past tests

- 2003 and 2005 – reliability tests of metal detectors, carried out by BAM (Federal Institute for Materials Research and Testing – Germany)

- demonstration of the work of CEIA metal detectors, carried out upon the request by AKD Mungos company.

- testing of technical performance of metal detectors used by CROMAC.

- 2006 – testing of Japanese robotic buggies and mine detection dual sensors ((Mine Hunter Vehicle -MHV1 i MHV-2, Gryphon, ALIS)

- 2006 – STEMD project – systematic test and evaluation of metal detectors used in the region of southeast Europe, carried out in collaboration with BAM (German Federal Institute for Material Research and Testing)

- 2006 – testing of a mine detection scanner in collaboration with Fraunhofer Institute from Germany, as part of the HUMIN/MD project.

- 2007 – testing of Japanese dual sensor systems ALIS (Advanced Landmine Imaging System) and Gryphon + LAMDAR IV

- 2009 – use of bees in mine detection – passive method – sampling from the beehives.

- 2012 - 2014 – TIRAMISU project within the EU FP7

- 2014 - 2018 – trials by Manchester University

- 2016 - 2019 – trials by St. Andrews University

- 2018 - 2019 – Faculty of Electrical Engineering and Computing, University of Zagreb – R&D of metal detectors, field trials

- 2018 - 2021 – NATO SPS project Biological method (bees) for Explosive Detection

- 2019 - SeaTerra GmbH – testing of a drone survey system

- 2022 – KONTUR AS – field testing and data collection with a UAV 3D GPR system

- 2022 – Manchester University – testing of fully integrated detector units

- 2022 – the GICHD with support from the HCR-CTRO conducted a trial of the MineKafon airborne demining system

- 2023 - testing of a magnetometer designed by a German company SENSYS

- 2024 - Testing an UAV-based synthetic aperture radar system (GPSAR) by the FindMine gGmbH Germany